In the welding process of H-beam, the flange plate will inevitably produce bending deformation due to the concentrated heat input at the weld.

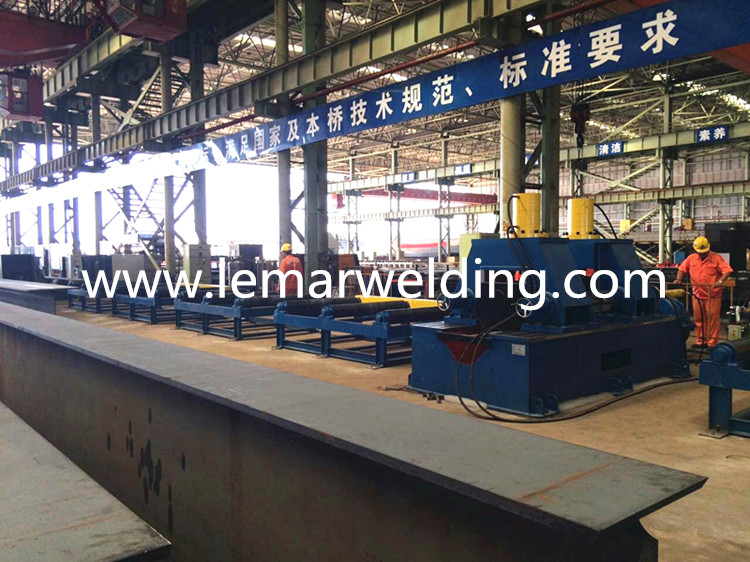

The H-beam steel flange straightening machine is a special equipment for straightening welded H-shaped steel flange plates.

This H beam Flange Straightening Machine is easy to operate, fast in straightening speed and excellent in straightening quality. It can be widely used in metallurgical construction, metal structure, hydraulic machinery, industrial installation and other industries.

Technology parameter:

Name | Technical parameters | Remark |

Minimum web height | 200mm | Min web height: 380mm (corrective secondary roller when web height of 200-380mm, plate thickness is less than 16mm). The ash clearance port is set under the main machine. Convenient to clean up the oxide skin falling during the straightening process |

Web thickness | 6-50mm | |

Flange width | 200-1000mm | |

Flange thickness | 8-60mm | |

Work-piece material | Q345 | |

Correct the wheel line speed | ≥8.9m/min | |

Input / output roll length | 9m+9m | 3m for each set |

Roller roller material | 35CrMo | Made of forging pressure and quality treatment with long service life |

Roller roller hardness | HRC50-55 | |

Speed Reducer | 1set | |

Drive the electric motor | 15kw | |

Oil pump drive motor | 5.5KW | |

Oil pump displacement | 25m1/r | |

Total installed power | 20.5KW | |

Maximum system pressure | 20 Mpa | |

Normal operating pressure | 18-20 Mpa | |

Hydraulic station | 1set | |

Electric control system | 1set |

Details of machine:

1.The machine base is composed of a base and an upper base. Both the base and the upper base are welded by steel plates, and the two parts are connected by bolts to facilitate processing, installation and maintenance.

All the correcting rollers are made of high-quality alloy steel, and through advanced heat treatment technology, to avoid the defects of the parts that are prone to cracks. In order to ensure the stability of its correction and long service life, all its parts are strengthened.

The web clamping is driven by two hydraulic cylinders, and the operation is simple.

The verticality of the H-shaped steel flange plate and the web can be straightened, and the two cylinders can be pressed down individually and at the same time.

Why choose us?

We are committed to providing customers with high-quality products and ensuring their maximum satisfaction.

We have a very good reputation and customer base in the market, mainly from:

Extensive distribution network

Fair business policy

The most advanced manufacturing technology

Satisfactory after-sales service

Qualitative product range